Products

Four shaft shredder for industrial recycling applications

For particularly difficult applications

Very compact and rugged design

High availability and process stability

Low noise and dust emissions

Rated capacity: 44 / 50 / 60 kW

Feed opening: 750 / 1,000 / 1,230 x 700 mm

Fraction sizes (based on the screen): 15 - 40 mm

Rated capacity: 60 / 74 kW

Feed opening: 1,000 / 1,200 / 1.440 x 860 mm

Fraction sizes (based on the screen): 20 -100 mm

Rated capacity: 110 / 150 kW

Feed opening: 1.200 / 1.500 x 1.020 mm

Fraction sizes (based on the screen): 20 - 100 mm

Top-quality recycling for even the most extreme applications and materials from a premium manufacturer: The mature RS50, RS60 and RS100 shredders, which have been tried and tested under difficult conditions, are characterised by their outstanding reliability, their ability to handle unshreddables and a particularly wide application range - from electronic scrap and metals, through to plastics and data destruction. Further features are their rugged and resilient design, high availability and process stability, as well as low noise, easy maintenance and particle precision.

As these machines are modular in concept, the speeds, torques, cutting unit apertures, cutters, perforated screens and sealing variants can be individually assembled for each industrial shredder depending on customer requirements. The rugged construction and the robust cutters make this high throughput shredder particularly attractive for multi-shift continuous operation and integration into existing plants. The middle-range RS class series is particularly effective in difficult recycling applications and in pre-shredding.

In contrast to fast-running systems, four shaft shredders are especially resistant to foreign objects, meaning that if a cutting disc hits a foreign object, then the machine stops immediately. On the one hand, this prevents damage resulting to the shredder cutters. On the other, the reliable drive permits frequent reversing, which is particularly beneficial when shredding problematic materials. In addition, the manufacturer has integrated a perforated screen quick-change system as standard, which permits rapid and efficient changing of the screen and guarantees easy operation.

Wide range of materials: RS50, RS60 and RS100 industrial shredders are able to shred everything from files and data, dashboards, automotive interior panels, batteries, tin cans, electronic scrap, electric ovens right up to Eternit panels, sprung mattresses, films, dishwashers, commercial waste, rubber waste, cardboard, plastics, refrigerators, metals, medical waste, paper, paper rejects, PET bottles, production waste, Tetra Pak, textiles, packaging materials, workshop waste and much more.

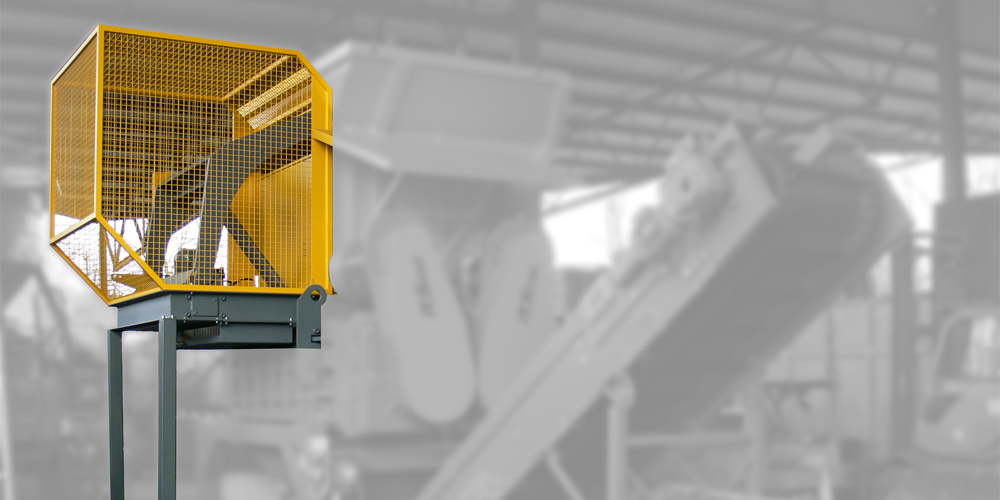

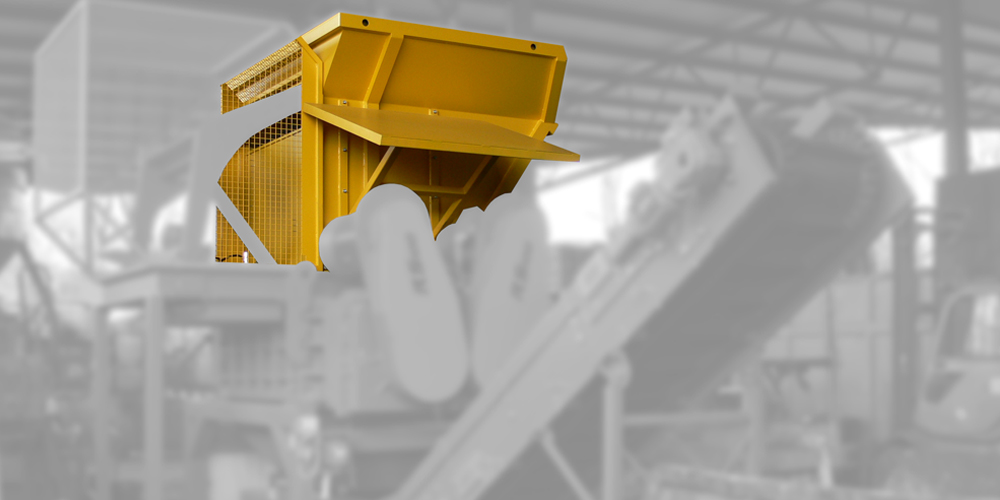

For integration into existing plants, the recycling machines can also be equipped with separator and conveyor technology such as discharge screws, customised hoppers and substructures and control expansions. Our specialists are happy to tailor a configuration for your plant. Your advantage: We offer comprehensive, single-source solutions direct from the manufacturer!

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

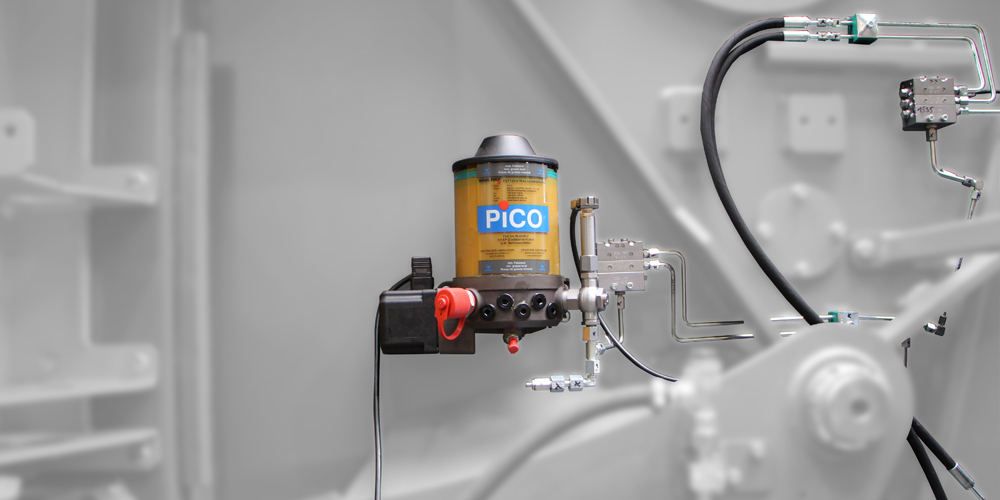

Depending on your requirements, we offer custom-made accessories for this shredder.

We are also happy to provide infeed and discharge conveyor belts. These will be optimally adapted to the on-site conditions and the desired throughput performance of the industrial shredder.