Material

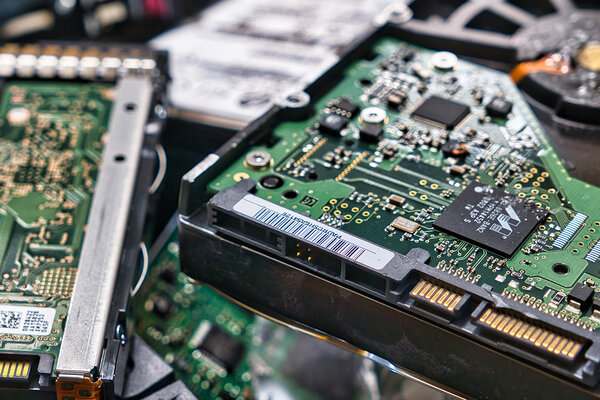

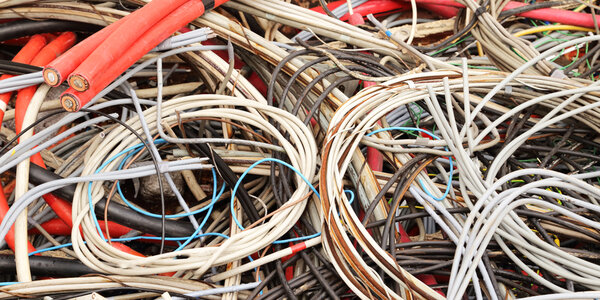

Metal shredding is a necessary step in the recycling process, independent of whether your scrap metal comes from the metal-processing industry, the automotive industry, the electrical industry or the waste industry.

Whatever your needs are, we have the right shredding system for your recyclable materials!

Find the right shredder

Input materials

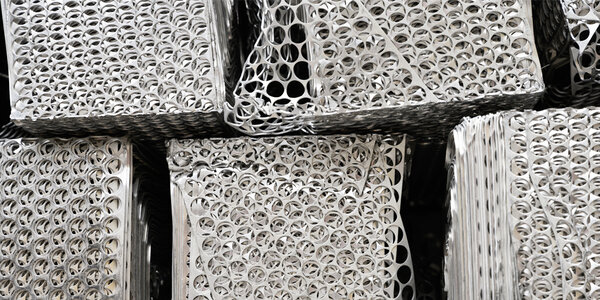

Sheet metal waste is a valuable resource! Ideally, it is shredded by our sturdy rotary shears and recycled. Capitalize on our large selection of different shredding machines. We will always provide you with customized size reduction solutions that are adjusted specifically to your needs.

Recycling steel doesn’t just save billions in environment- and climate-related costs: Replacing the primary material with scrap saves millions of tonnes of CO2 emissions. This is not reflected in the price yet, but in future, consumers and politicians should be given the clear message that scrap minimises the use of raw materials, reduces environment-related costs and thus actively contributes towards climate protection.

There is no general answer to this question, as not every metal is the same. The right shredder will therefore depend on the shape, hardness and ultimate purpose of the metal recycling process. From reducing the metal volume in order to facilitate further processing in the smelting works to improved separation of varying metals and composites, we will always analyse your requirements together with you and determine the right unit with regard to input material, throughput and desired size of the granulate. The question of whether a single-shaft or four-shaft shredder is the best choice for your material also needs to be addressed.

Your benefits when using the XR shredder

The stationary or the mobile XR shredder is particularly suitable for the single-phase processing of metals and scraps. Minimum operating costs combined with maximum performance make the shredders of the XR series powerful partners for metal recycling. The single-phase shredding process makes this unit particularly efficient and economical to operate.

Lower transportation costs thanks to increased bulk density of the material

Perfect preparation for further processing thanks to defined fraction size

Excellent material breakdown for a high degree of purity

Straightforward processing of different types of metal

High level of plant availability as the cutting chamber is easy to clean before the input material is changed

Low energy cost and minimal noise and dust emissions thanks to UNTHA Eco Power Drive

Metal- and scrap-shredding with a four-shaft shredder for defined grain size

A four-shaft metal shredder is used when defined and homogeneous granulate sizes of less

than 200mm are required.

Depending on the individual model, the four-shaft shredders of the RS series are used for the following areas:

Metal turning and milling chips

Breaking down compound products

Shredding rejects

Separating precious metals, scrap aluminium and light scrap steel

Thanks to its compact design, the unit is easy to integrate into existing plants.