Products

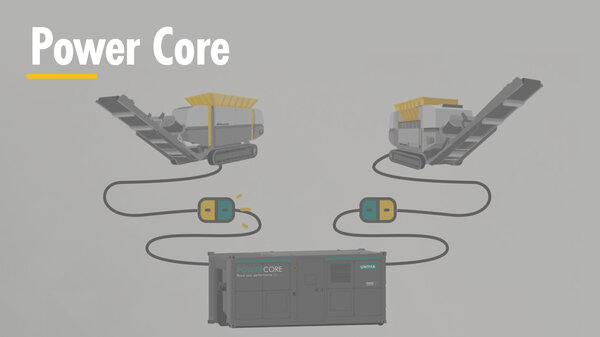

The UNTHA Power Core serves as an energy source for the shredding process in locations where no suitable power supply is (yet) available or for temporary use.

Suitable for autonomous operation of the XR & ZR shredders

Enables stand-alone operation without any additional connections on site

Plug & play – quickly ready for use

Up to 20–25% lower fuel consumption

Full integration into the MyUNTHA customer portal

Complies with current EPA Final Tier 4 / EU Stage V emissions standards

The Power Core has been precisely tailored to the requirements of the XR & ZR shredders.

The Power Core's performance automatically adapts to the shredding process. This enables the generator to operate continuously at its rated power, thereby extending its service life.

Thanks to the high dynamics of the Power Core, a generator that is only half the size of the engines usually required can be used. This enables fuel savings of approx. 20–25%.

The integrated insulation monitoring system guarantees maximum safety and flexibility – without any additional installations – and ensures reliable monitoring of the system.

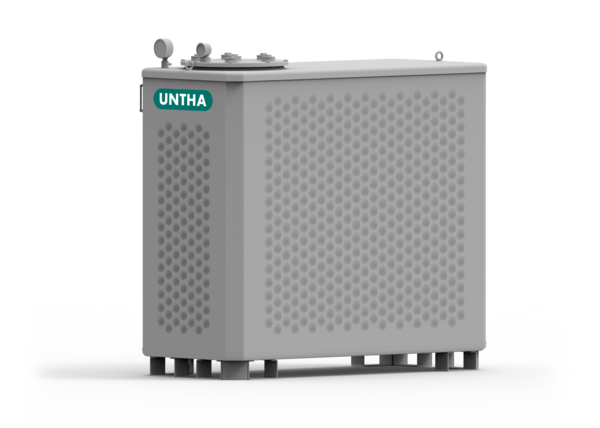

The generator set is installed in a soundproof, lockable, and compact 20-foot container. This reduces noise emissions to a minimum and protects the Power Core from environmental influences.

Ideally suited for bridge phases or temporary use, for example, during test operations or rental.

The best way of finding out more about the quality and cost-effectiveness of our revolutionary XR class is to test it on your own premises. We will take the XR shredder to where you are and process your materials in real-life conditions. This way, you may be 100% sure that you have taken the right decision, independent of whether you choose a stationary or mobile unit.

Advantages of the Power Core

The UNTHA Power Core is the ideal solution for smooth shredder operation in locations without a fixed power supply or for the temporary use of a shredder. Thanks to various transport options, the Power Core can be moved as required. This provides users with maximum flexibility when selecting the location for their operation. The connection between the shredder and the Power Core is also quick and easy thanks to the Power Lock system. No additional installations are required thanks to the integrated insulation monitoring. This allows the entire unit to be operated without a grounding cable or grounding spike, while ensuring reliable monitoring of the system.

The unit has also been integrated into the MyUNTHA customer portal. This enables users to monitor all processes—both the Power Core and the shredder—in real-time. GENIUS processes the collected data and provides reliable information, for example, when the tank level reaches a critical point. In addition, MyUNTHA and the UNTHA service team provide support for questions relating to service and maintenance.

The Power Core from UNTHA stands for responsible and future-oriented use of energy. It complies with the strict EPA Final Tier 4 and EU Stage V emission standards, actively contributing to reduced emissions. The generator set is housed in a compact, sound-insulated container that reduces noise emissions to a minimum and protects the Power Core from environmental influences.

The MyUNTHA customer portal gives you access to all your shredder data and useful features such as the spare parts catalog & online store, maintenance manager and the GENIUS digital assistance system. MyUNTHA supports you in your daily work with your shredder and helps to make processes even more efficient.

UNTHA's Power Core was developed specifically for use with the XR and ZR series and is precisely tailored to their requirements. During the shredding process, the Power Core regulates its performance independently based on the shredder's actual energy requirements. Thanks to its high dynamics, a significantly more compact motor can be used than would usually be necessary.

The result: particularly efficient and resource-saving operation, enabling fuel savings of around 20–25%.

Depending on the material (composition), cutting mechanism, and perforated screen, the Power Core can drive the shredder for up to 25 hours. With the optionally available additional tank, the operating time can be increased to 100 hours.

Regular service and maintenance work ensure that the Power Core remains efficient for a long time. Experts from the manufacturer John Deere carry this out. This also means that the warranty remains fully valid. The UNTHA team is the point of contact for any necessary service and maintenance work. Power Core users, therefore, have a single designated contact person for all their shredder and Power Core-related questions.

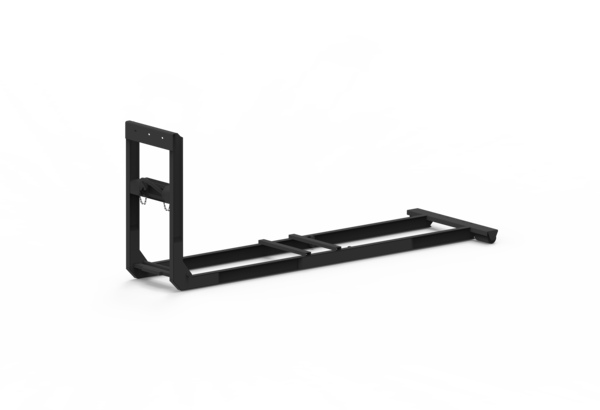

Optional additional equipment for the Power Core

The roll-off frame allows easy and flexible handling of the Power Core directly at the site of use without the need for a heavy-duty crane. The design complies with the usual standard for hook lift trucks (according to DIN30722-1). An anti-theft device has also been integrated.

We offer interested parties the opportunity to see the performance and reliability of our shredders for themselves. We will bring a model from the XR or ZR class that is optimally tailored to your requirements and carry out a test with your material together with you. This way, you can ensure that the shredder meets all your expectations.

For companies and locations that do not (yet) have a suitable power supply, we have developed the UNTHA Power Core: an innovative power generator for the autonomous operation of the XR and ZR shredders – for maximum flexibility and efficiency.