References

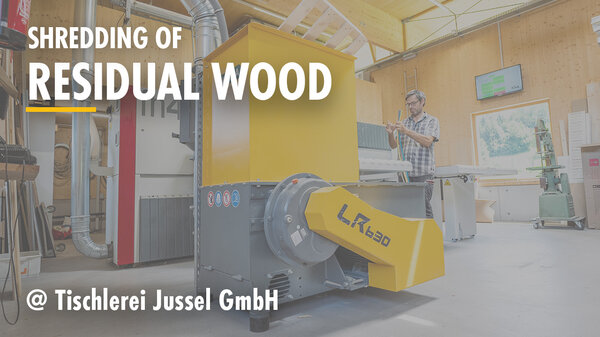

Jussel carpentry relies on the UNTHA LR630 wood shredder. It single-handedly takes care of shredding residual wood outside of operating hours. The wood chips are then automatically extracted and cleaned of metal parts by means of a pipe magnet. The result: pure wood chips for the production of wooden briquettes.

The Jussel family has a deep-rooted connection to wood. The company was founded in 1989 by Ehni Markus Jussel senior. Today, the Jussel carpentry workshop in Vorarlberg has twelve employees. In the modern carpentry workshop, they produce individual pieces of furniture, custom-made kitchens, modern interior doors, representative furnishings for public buildings and unique pieces of craftsmanship.

The Jussel carpentry shop was looking for a shredder that could efficiently shred any wood waste – chipboard, MDF, OSB, solid wood – and packaging material. The shredder was to be used primarily outside of working hours, so it was important that it could operate reliably and unattended and could also handle metal contaminants well.

REQUIREMENTS

Reliable shredding

Resistant to foreign bodies

Homogeneous source material

Metal separation

The company chose the UNTHA LR630: a single-shaft shredder with a powerful horizontal pusher and a throughput of approx. 2.5 scm/h. Thanks to its compact design, the shredder could be placed directly in the production area, allowing the residual wood to be filled directly into the hopper. The shredding is done outside of the team's working hours. It was therefore important that the LR630 works reliably and unsupervised. The cutting system is resistant to foreign objects and also shreds screws and nails without any problems. There is a 12 mm perforated screen in the shredder, which ensures that the wood chips are smaller than 12 mm. This is then suctioned off and a magnetic tube removes all metal parts. The pure wood chips are processed into briquettes in a press, which the company uses for its heating system. The shredder is extremely low-maintenance: the magnetic tube is cleaned once a week and basic maintenance is carried out once a year – by Hopfner Maschinen.

We chose the LR630 because it fulfils all our criteria: it has the right throughput, a pusher and a pipe magnet. This means it fits perfectly into our workflow – we hardly have to worry about the waste wood or its processing.

Lukas Jussel

Managing Director of Jussel Carpentry