Excellent service from UNTHA

UNTHA has been developing and manufacturing shredding solutions for the economical recycling of waste materials of all kinds for more than 50 years. The promise of “reliability throughout the machine's lifetime” is lived worldwide: from production, consulting, sales, installation, and commissioning to service. The UNTHA Headquarter and all subsidiaries offer comprehensive consulting and expert service. Our proximity to customers ensures that help is provided quickly and without complications. Because at UNTHA, reliability and customer satisfaction are the top priorities.

Every shredder should be inspected and serviced regularly. This is because natural wear and tear during operation causes individual parts to wear out, reducing the efficiency of the shredder and increasing operating costs. Unforeseen downtime can also usually be avoided through regular maintenance. The UNTHA team is always on hand to provide customers with proficient and fast support. UNTHA's comprehensive range of services includes a wide variety of measures.

Cutting unit reconditioning service

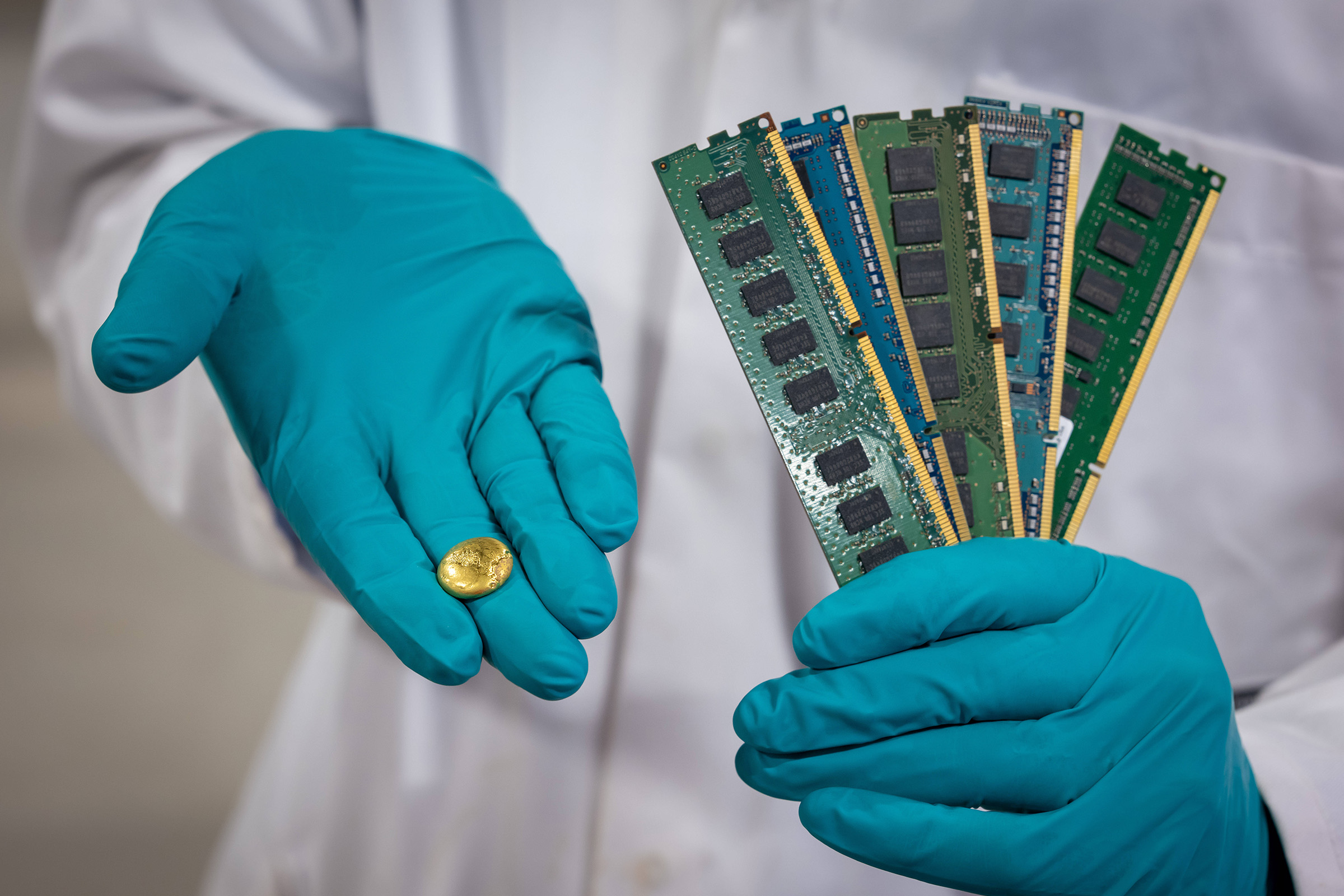

The cutting units of shredders are probably the most heavily used machine parts. Fortunately, however, the cutting units of UNTHA’s 2- and 4-shaft shredders can be reconditioned and reused at low cost. It is usually possible to predict very accurately when they will wear out. Once this point has been reached, UNTHA service technicians will remove, recondition and then reinstall the cutting unit. This process can be repeated several times before a completely new unit is required. With this service, customers receive a cutting unit that is as good as new and offers excellent value for money. This service helps to significantly reduce wear and operating costs.

Certain cutting units are designed so that the cutting plates can be turned to bring an unused, sharp cutting edge into position. UNTHA also offers this service. And when a cutting unit has reached the end of its life cycle – and cannot be reconditioned or turned – it can be replaced with a new one.

Original UNTHA spare and wear parts

Alongside its shredders, UNTHA also offers matching spare and wear parts that are identical to the original components installed in the shredders – tested thousands of times and proven over many years. UNTHA original parts ensure that all components work together perfectly and restore the efficiency of the shredder. With its well-stocked spare parts warehouse, UNTHA ensures that customers are supplied with the most important parts quickly and easily, minimizing waiting times.

Modernization and optimization

UNTHA shredders are versatile and durable. As a result, the machine's area of application or technical standards may change over time. Modernization and retrofitting measures are available to adapt the shredder to these new conditions. They bring the shredder up to the latest state of the art and have a positive effect on its service life, performance, and operating costs. This is because outdated or worn technology usually leads to increased operating costs, a higher frequency of malfunctions and breakdowns, and increased costs for wear parts. If modernization and optimization measures are implemented in a timely manner, costs are reduced, and the machine continues to run profitably without significant effort. In addition, older shredder models can be equipped with new functions, such as remote control or integration into MyUNTHA.

UNTHA– expertise in shredding technology

The UNTHA team is characterized by its comprehensive knowledge, high level of technical expertise, and proximity to customers all over the world. With a wide range of services, the team ensures that shredders remain efficient and that costs for customers are reduced.

Thanks to its own service workshop and spare parts warehouse, the team is always able to provide rapid assistance and support to customers in keeping their operations running.

All services come from a single source: the team provides expert advice, is quickly on site and also delivers wear and spare parts immediately. For maximum customer satisfaction.