Products

Long-lasting solid wood shredders for intense continuous operation

Robust 4-shaft technology from a premium manufacturer

Maximum availability – suitable for multi-shift operation

Compact design – use directly in the production line

Minimum maintenance, particularly operator-friendly

3-year “Carefree” warranty

- Rated capacity: 11/15/22 kW

- Feed opening: 450 x 600 mm

- Fraction sizes (based on the screen): 15 - 40 mm

- Maximum throughput capacity: 3 srm/h

- Rated capacity: 30/37/44 kW

- Feed opening: 750 / 1000 x 700 mm

- Fraction sizes (based on the screen): 15 - 40 mm

- Maximum throughput capacity: 7 srm/h

The RS30 and RS40 wood shredders are used primarily in the woodworking and timber-processing industries, for instance in sawmills, in solid and laminated timber production facilities, carpentry workshops and joineries. The robustly constructed 4-shaft shredders have proven their worth in wood-shredding applications over several decades and are particularly effective when it comes to shredding solid wood. The shredders may be operated as stand-alone solutions or be integrated in complex plants. They stand out for their high availability and reliable shredding performance and are particularly efficient thanks to their high throughput.

Efficient waste wood disposal for the timber industry

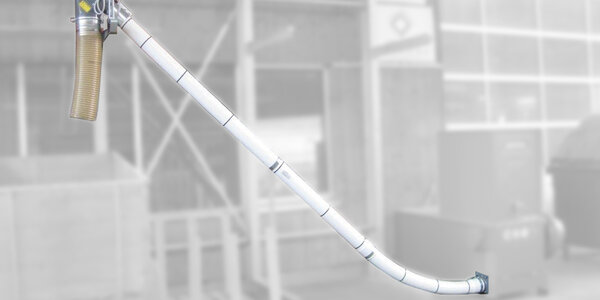

The RS class shredders are suitable for automated waste wood disposal along the production line. Thanks to their compact design, they can be seamlessly integrated into the production line to efficiently shred the waste wood. The wood chips are then transported to the chip silo via an extraction system. This innovative solution optimises production processes and saves time and manpower when handling waste wood.

The 4-shaft cutting system may be adapted to the respective input material, depending on material density, size and volume. The industrial wood shredders are particularly suitable for the shredding of residual wood such as solid wood, cap pieces, edge trims, veneers, bark, wood with metal inclusions and wet wood.

The shredders also handle large and/or long pieces with ease. Thanks to the automatic material feed of the cutting unit, the machine does not require a hydraulic pusher system, which reduces the service effort required for the shredder.

Maximum availability

Thanks to their high torque and large perforated screen surface, the shredders of the RS class are particularly productive, making them perfect partners for intensive continuous operation (multi-shift). In addition, the wood shredders are fitted with an automatic reverse function to prevent motor overload.

Low in maintenance and highly efficient

The low maintenance requirement and the high throughput ensure particularly efficient process flows and thus also low operating costs. In addition, the slow-running 4-shaft machines are highly resistant towards non-shreddables: In case a non-shreddable is detected, the shredder switches off automatically, thus preventing significant damage to the cutting unit and long downtimes.

The reliability of the RS30/RS40 wood shredders also results from their solid steel frame construction and their robust cutting chamber. The low speed of the cutting shafts keeps noise and dust production to a minimum.

3-year care-free warranty

We are convinced of the reliability and quality of our products, which we are also able to verify. We will therefore make you an offer tailored to your requirements and are the only manufacturer to provide you with a special form of security: Profit from the 3-year care-free warranty* on purchasing an UNTHA wood shredder, and request your offer now!

*) or 2,000 hours, depending on which is reached first.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

Depending on your requirements, we offer custom-made accessories for this shredder.

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.