Products

The flexible wood shredder for continuous operation in joinery or carpentry establishments

Universally applicable

Compact design

Cutting system deployed a thousand times over

Homogeneous wood chip quality

Customised system solutions

3-Year Worry-Free Guarantee

The LR700 wood shredder is the compact and universally applicable shredder system from the LR series for wood. It is designed for medium-high throughput and long operating hours. This wood shredder for joiners and carpenters combines the need for great flexibility with a very compact design. The shredder is therefore especially suitable for companies wanting to shred a larger quantity and larger pieces of waste wood per week. The LR700 single shaft shredder can be customised to cater for different joiner, carpenter and woodworking requirements, depending on your company requirements.

The homogeneous wood chip end product produced by the shredder is ideal for incineration in a wood chip heating system or for the manufacture of wood briquettes. The LR700 wood shredder produces high-quality wood chips which are the ideal method of recycling accumulated waste wood.

The high-torque machine drive system provides an enormous throughput in combination with the high pusher speed. Together with the tried and trusted UNTHA cutting system, the powerful and wear-free swing pusher ensures reliable shredding of different types and quantities of wood. The robust machine frame of the shredder and the use of high-quality components also guarantee the long lifetime of the machine.

Thanks to the offset rotor bearing, the gear damping and the reliable cutting system, the wood shredder is very low maintenance and has a long service life. The intelligent drive control shuts the shredder motor down automatically in case foreign objects enter the machine. In addition, the shredder has been equipped with an automatic reverse function to prevent motor overload.

Energy-efficient operation is particularly important for wood shredders designed to run over longer operating periods. This is why the LR700 shredder features a reliable and highly efficient cutting system which has been tried and tested a thousand times over. It will shred your waste wood with great efficiency even at low drive capacity. In addition, the motor shuts down automatically if no wood is fed into the machine for more than 3 minutes. This saves energy whilst simultaneously reducing operating costs.

The LR700 shredder is able to shred the following types of wood: Solid wood, logs, chipboard, veneers, MDF sheets, cardboard, pallets, bark and much more.

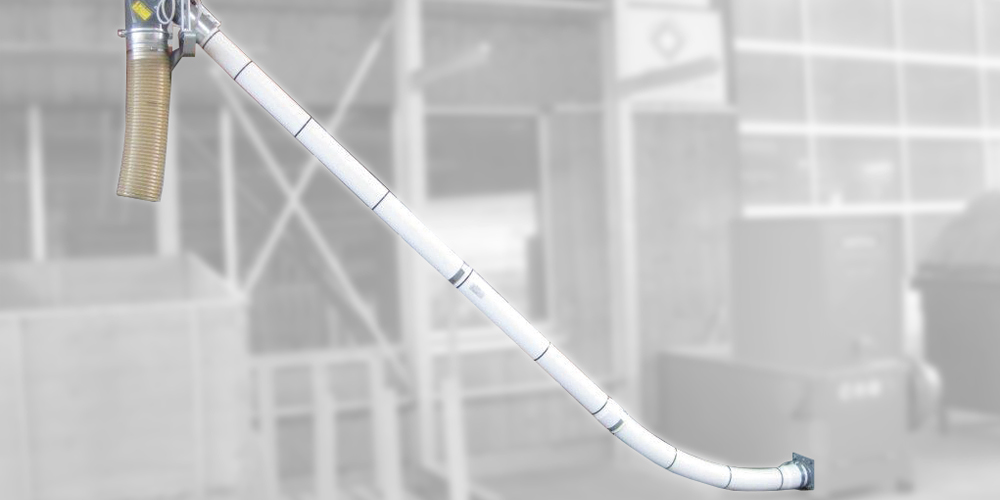

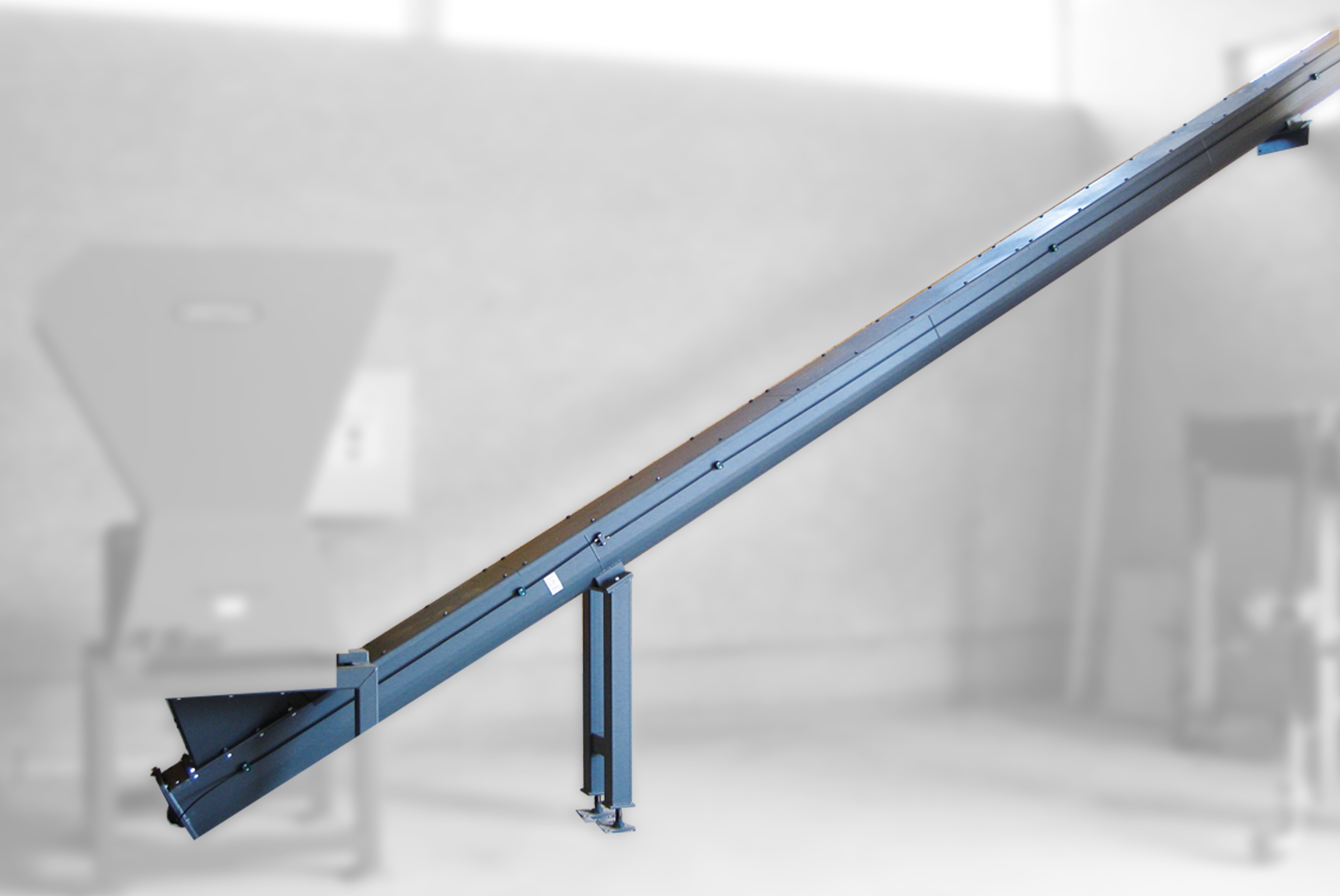

Each of our wood shredders is customised to your wood working needs. The single shaft shredders by UNTHA can also be equipped with a metal separator, a discharge screw, a conveyor belt or a customised hopper. We offer comprehensive, single-source solutions direct from the manufacturer!

We are convinced of the reliability and quality of our products, which we are also able to verify. We will therefore make you an offer tailored to your requirements and are the only manufacturer to provide you with a special form of security: Profit from the 3-year care-free warranty* on purchasing an UNTHA wood shredder, and request your offer now!

*) or 2,000 hours, depending on which is reached first.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

Depending on your requirements, we offer custom-made accessories for this shredder.

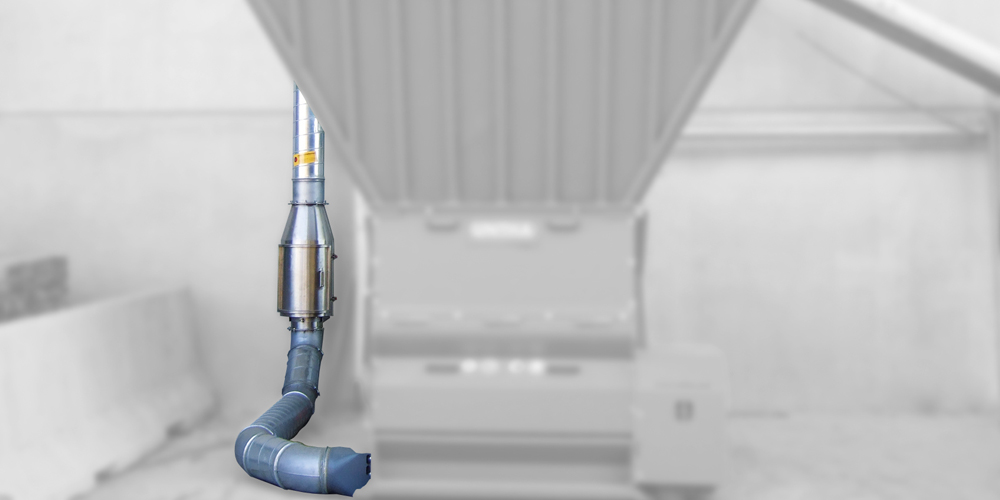

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.