Material

Due to its versatility in use, plastic is primarily utilised in industrial mass production.

The generated plastic waste can be recycled through shredding, washing and subsequent generation of granulate to produce a recyclable material (for the recovery of materials or energetic utilisation).

The UNTHA plastic shredders have been developed specifically for this treatment process.

Find the right shredder

Input materials

An exact cut is required to be able to efficiently shred filaments, little bands, big bags, fleece materials, ropes and textiles. Our heavy duty plastic shredders are especially designed to smoothly and efficiently shred even these types of materials.

SHREDDING OF PLASTICS

Our plastic shredders have been especially developed for the processing of different plastics. Therefore, our robust shredders are for example ideal for the single-stage shredding of hard plastics which are bonded with iron or metals. Such products made from plastic are for example

Ski boots

Child seats

Garden furniture

Economically-viable recycling is also possible for these products thanks to our shredders, which feature already-integrated magnet separators. The granulate thus obtained can be separated later into the different types of plastic in extrusion systems, and then reused by the company as completely new plastic.

In addition, as mentioned above, it is possible to utilise plastic from our shredders for thermal purposes. This is for example an economically-viable alternative when recycling plastic from particularly contaminated materials. Some plastics contain double as much energy as lignite, for example. Therefore, plastic is a suitable substitute for primary fuels such as oil, gas or coal.

The ideal shredder in all conditions

Thanks to the flexibility of our shredders, they are ideal for the different requirements in plastic shredding applications. Due to our range of different cutting systems, rotor diameters, rotor shapes or blade sizes, the machine can be individually adapted and tailored for your material, and therefore for your requirements.

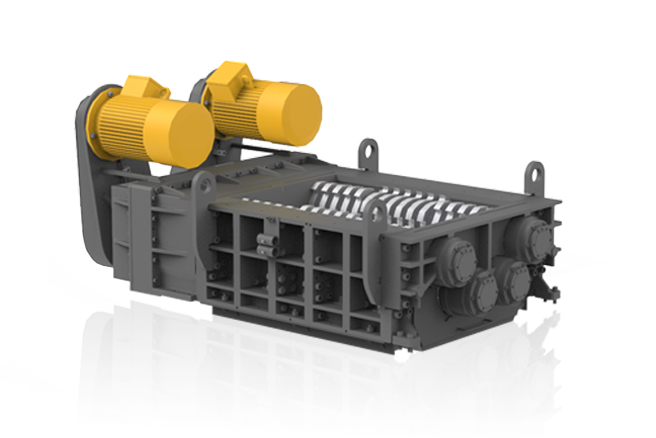

In particular where standardised machines reach their limits, our four-shaft shredders, which have been tried and tested under difficult conditions, come into their own. High reliability and robust resistance to extraneous materials distinguish these plastic shredders.

Single-shaft shredding systems are universal in use, and are able to process a broad range of different materials. It is always possible for you to integrate one of our shredders into your plant, or to operate it as a stand-alone shredding solution.